Secure Your Equipment - Fasten Your Hardware

In the realm of construction and general maintenance, the importance of safety cannot be overstated. One key aspect that often goes unnoticed is tool tethering, a practice that can significantly reduce safety risks when working at height. We spoke with Andrew Egerton, Head of Category Tools and General Maintenance for Brammer Buck & Hickman, to gain insights into this crucial safety measure.

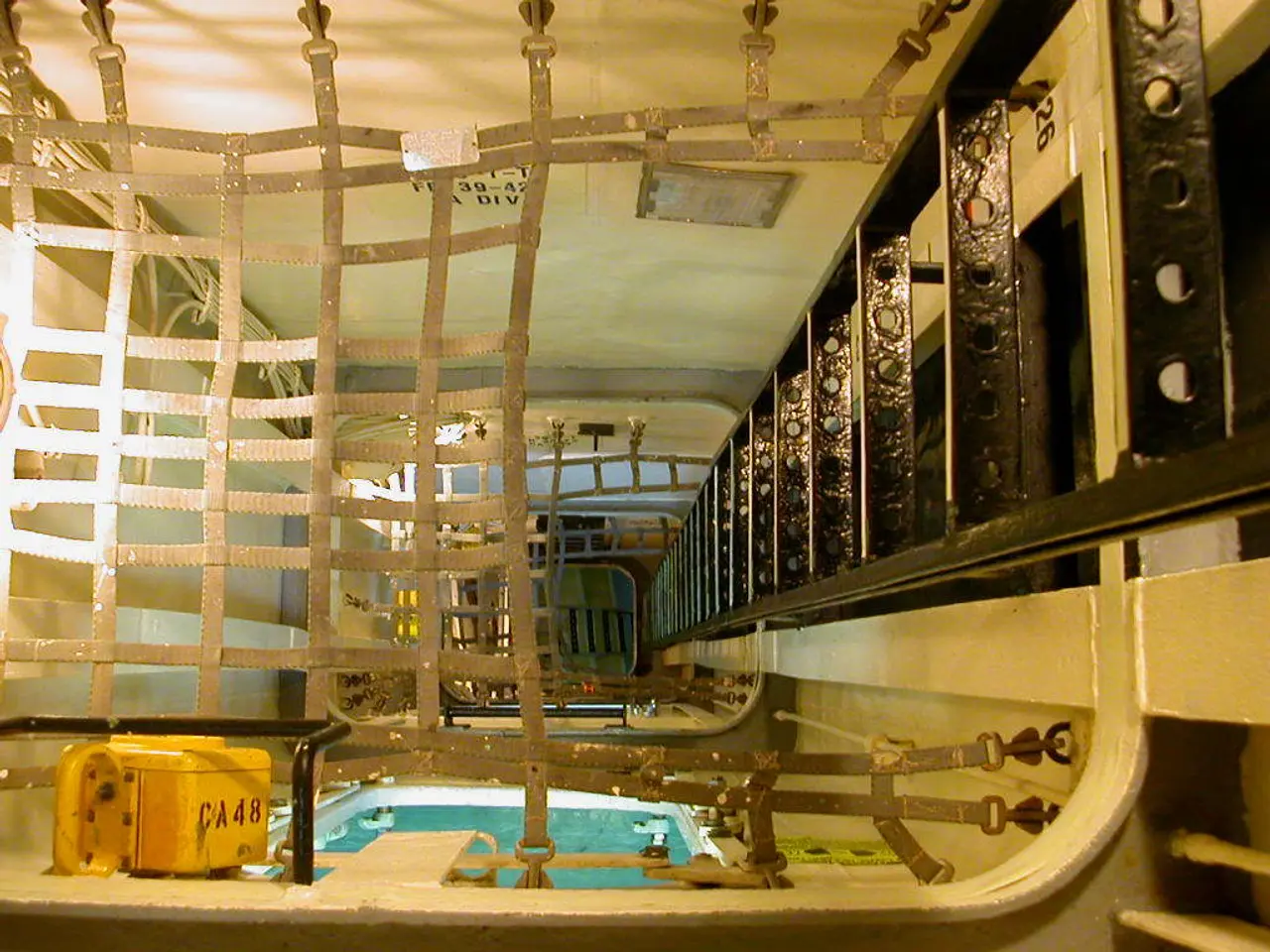

Tool tethering kits, available in the form of rigid, upright cases or tool trolleys, can be customised to meet specific needs. These kits encompass a variety of basic solutions for tool tethering setups, such as lifting bags, safety backpacks, tool holsters, safety pouches, heavy-duty belts, and safety pouch belts.

When it comes to heavy-duty tools, solutions like the Double-Loop Wire are ideal. This wire is designed to secure tools like hammers, wrecking bars, and dynamometric wrenches, ensuring they stay tethered and prevent potential accidents. For tools where drilling should be avoided, a spring can serve as a high resistance and flexible solution.

Safety accessories like the Safety Pin, used on socket holders to prevent a socket drop, and the Safety Plate, a metal bracket attached to tools as a tethering point, further enhance the safety of tool tethering systems.

However, it's important to note that in the UK, there are no regulations mandating the use of tethering tools when working at height. Despite this, it's strongly recommended to roll out a sitewide tool tethering training program, covering all aspects of working at height and with tools.

The HSE Working at Height 2005 guidelines state that employers should take steps to prevent falls of materials or objects to prevent injury. This includes tethering tools when working at height, which involves a tether point, tool lanyard, and anchor point. The tether point is usually a small hole on the tool designed for a lanyard, while the anchor point can be a work belt, wristband, harness worn by the operator for lighter tools, or a fixed piece of beam or load-rated rail for heavier tools.

The lanyard gets attached to the tether point on the tool and then to the anchor point. Materials like Kevlar and Dyneema String are popular choices for tool lanyards, with Dyneema being 15 times stronger than steel.

When it comes to selecting the right tool tethering system, the most important factors to consider are strong and durable tethers, secure attachment points, flexibility for movement, ease of use, and compliance with safety standards to prevent tool drops and accidents.

Consulting the on-site Health and Safety Officer or PPE specialist can help tailor a tool tethering program around the site, ensuring the highest level of safety for all workers. After all, preventing accidents is the key to a safe and productive work environment.

Read also:

- Overweight women undergoing IVF have a 47% higher chance of conceiving naturally post-weight loss

- Bonsai Trees from Evergreen Species: Exploring Growth Characteristics & Distinct Qualities

- What temperatures may make walking your canine companion uncomfortable?

- Title: Information About Beovu: Potency, Form, Usage, and Additional Details